With the continuous development of society, the types of construction machinery tend to be diversified and specialized. Sometimes we need cut a large number of round holes, square holes and special-shaped holes on the plates of various thicknesses. The laser cutting machine can not only quickly perforate, but also greatly reduce the production cost of mechanical equipment and improve economic benefits with its advanced laser processing technology, drawing system and digital control technology.

The advertising metal signs require high for the processing accuracy of fonts. The traditional processing methods are time-consuming and labor-consuming, with high rework probability. In advertising industry, the high-precision laser cutting machine manufactured by Raytu laser is compact and has higher processing accuracy. The cutting materials do not need to be reworked again, which greatly improves the work efficiency and is cost-effective for the company.

Fiber laser cutting machine is suitable for cutting metal sheet, and the kerf is smooth without burr formation. Compared with traditional processing method which is low in efficiency and causes large consumption of mold, laser cutting realizes customized and personalized product development, so it is widely recognized by kitchen utensils manufacturers.

Under the high demands for material cutting in the field of shipbuilding, traditional processing methods like flame cutting and plasma cutting are outdated because of high reworking rate. While using high-power laser cutting machine, the cutting quality and the perpendicularity of the cutting surface are much better and the cutting surface has no slag, thin oxide layer, smooth surface, no secondary processing needed.

Fitness equipment which has various specifications and shapes, requires higher precision for the diversity of laser cutting. Different from the low efficiency of the traditional way for steel processing, plate & tube laser cutting machine can be customized to process different specifications of pipes and plates and ensures the quality of the assemblies produced.

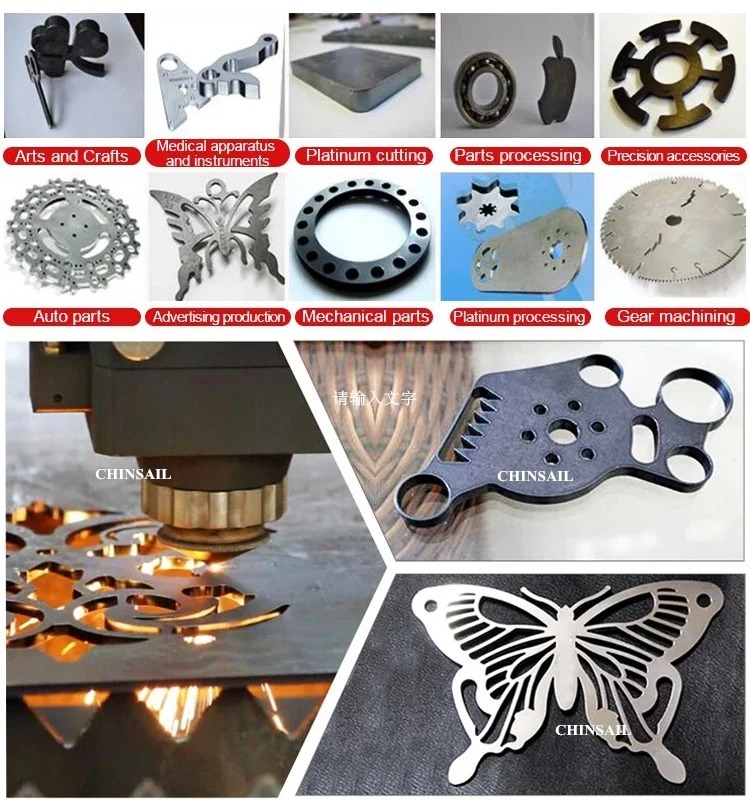

Automobile parts such as B pillars, front cover, car sheet metal, car brake pad, etc. can be handled with cutter machine. To ensure the cutting accuracy is of great importance to improve the visual aesthetics and safety of the car. The traditional processing technology is inefficient and the accuracy is difficult to guarantee, while metal laser cutting can be processed in batches with high precision, high efficiency and burr-free as well. These are the reasons why laser cutting machine is the top cutting tool used in automotive industry.

Stainless steel is the most commonly used material in modern society. Here are some examples that stainless steel may appear in our daily life: bowls and chopsticks, kitchenware, bathroom supplies, stainless steel furniture, elevator interior, railings, advertising words, decorations and so on. Stainless steel is popular for its features of rust-protection, anti-corrosion, mechanical properties, durability and colorfastness.

The realization of finished stainless steel products covers mold, grinding, welding and other processing technologies, which costs a lot of manpower, mold and time. Thanks to the development and application of laser cutting and laser welding technology, stainless steel processing becomes much easier while the quality is higher. With the application of stainless steel laser cutting machine, the cutting efficiency, cutting quality and cutting precision have been greatly improved.

Raytu laser cutting machine for stainless steel has the advantages of superb beam quality, high cutting precision, smooth kerf, and is not restricted by complex and intricate cutting contour. No need of labor-consuming pre-processing in most cases, the production efficiency of laser cutter is 5-10 times higher than that of traditional stainless steel processing method, which can meet the demand of rapid proofing and mass production capacity.

Here are some samples of stainless steel cut by GSP Traders laser cutting machine: the thickness (mm or inch) varies depending the watt of the machine.

As a kind of high-quality alloy steel, carbon steel has been widely used in the daily life and applied to various industries due to its excellent texture. Carbon steel does not reflect light strongly and absorbs light beam well because the alloy contains carbon. Carbon steel is more suitable for laser cutting machine, and the processing effect is excellent. Not only the cutting edge is flat and smooth, the machine is also convenient, safe and cost-effective to use.

When you cut carbon steel, the laser source emitted by the laser irradiates the surface layer of carbon steel, and instantaneous high temperature is generated. Under the action of auxiliary gas, it quickly reacts with silicon, manganese, sulfur, phosphorus and other elements contained in carbon steel, oxidizes, melts and vaporizes them, and then it can penetrate carbon steel, and then the laser displacement is controlled by numerical control to achieve the purpose of cutting.

The following are the advantages of laser cutting machine for carbon steel:

1.Lower maintenance cost: independent core light source, lower purchase and maintenance cost by up to 20%.

2.Higher cost performance: high quality cutting technology, the same cutting efficiency and quality as imported laser.

3.Faster cutting speed: cutting speed up to 120m / min.

4.Better after-sales service: master the core technology, fast service, low service cost.

As an advanced laser equipment manufacturer in China, Raytu laser has been engaged in the field of laser cutting machine for carbon steel for many years, contributing a number of high-quality products to the metal processing market.

Some customers wonder whether laser cutting machine can cut aluminum or not, the answer is definitely yes. In the processing of the cut, notice that aluminum is not resistant to high temperature, processing technology needs to be debugged patiently, at the same time, pay attention to cutting speed. In addition, it is recommended to use nitrogen as auxiliary gas when cutting aluminum plate with aluminum laser cutting machine, because of the special color of aluminum, and in order to ensure the color uniformity of cutting products, nitrogen can well prevent oxidation and retain the characteristics of the material itself, so nitrogen is a better choice than oxygen.

The cutting thickness is relevant to the power of the machine, generally 2000W can cut 6-8mm, 4000W suitable for 12mm, while 6000W can deal with 16mm material. Optical fiber laser cutting is more suitable for cutting aluminum plate, and its wavelength absorption effect of 1064nm is better. After reading these cutting precautions, I believe you can correctly use the aluminum laser cutting machine.

At present, optical fiber laser and YAG laser are widely used in aluminum laser cutting. These two devices have good performance in cutting aluminum or other materials, such as stainless steel and carbon steel. In addition, it should be noted that aluminum has high reflectivity and low absorption of laser, so it is necessary to wear laser protective glasses in the process of processing to protect labor safety.

High reflective metal materials have always been difficult to cut by laser cutting machine, including brass, copper, aluminum, gold and other metal materials. It is a big issue for laser cutting machine manufacturers to solve the problem of cutting high reflective materials.

Why is it difficult for laser cutting machine to cut high reflective metal materials? Because the high-intensity reflection will damage the optical parts on the laser cutting machine equipment, but it does not mean that the high reflection metal materials cannot be cut. Now the problem of brass laser cutting has been solved. Let's share some cutting experience.

As we all know, copper is a kind of material with heat conduction performance. Before processing this kind of material, we should first analyze its performance and material, and understand the performance of each processing material, which is a necessary skill for laser cutting machine operators. Therefore, we need to master the performance of brass, such as its heat transfer performance, reflectivity and so on. When we understand the characteristics of the materials we need to cut, we can better analyze the cutting solution - adding nitrogen and oxygen auxiliary gas.

Why is it necessary to add auxiliary gas to cut high reflection metal materials? When the laser cutting machine cuts metal brass, the added auxiliary gas reacts with the material under high temperature, increasing the cutting speed, for example, using oxygen can achieve the effect of combustion supporting. For laser cutting equipment, nitrogen is an auxiliary gas to improve the cutting effect. For brass materials under 1 mm there is no need to worry about whether it can be cut off. At this time, we should pay attention to the processing effect, so nitrogen is the best auxiliary gas. When the thickness of copper reaches 2mm, it is impossible to process with nitrogen. At this time, oxygen must be added to support combustion and oxidize it to realize cutting.

Please Subscribe our news letter and and get update.